Seeking top-notch electric motor and pump repair services? Look no further. In today’s fast-paced world, a malfunctioning electric motor or pump can bring operations to a grinding halt. But fret not, because we have unlocked the ultimate guide to finding reputable repair services right in your area. Whether it’s a residential, commercial, or industrial setup, it’s imperative to have these essential systems running smoothly at all times.

Our expert technicians are equipped with the skills and knowledge to diagnose and repair a wide range of electric motor and pump issues, ensuring minimal downtime and maximum efficiency. With a focus on quality craftsmanship and unparalleled customer service, we take pride in delivering solutions that exceed expectations.

So, if you’re in need of reliable electric motor and pump repair services, sit back, relax, and let us connect you with the best in the business. Say goodbye to disruptions and hello to seamless operations.

Understanding electric motor and pump repair services

Electric motors and pumps play a crucial role in various applications, from powering industrial machinery to maintaining water circulation in residential and commercial settings. Over time, these systems may experience wear and tear, leading to performance issues. Understanding the intricacies of electric motor and pump repair services is essential in ensuring the longevity and efficiency of these vital components.

Professional repair services encompass a comprehensive approach to diagnosing and addressing issues related to electric motors and pumps. From identifying faulty components to implementing precise repair techniques, skilled technicians are equipped to restore these systems to optimal functionality. By delving into the nuances of electric motor and pump repair, individuals and businesses can make informed decisions when seeking professional assistance.

When it comes to electric motors and pumps, an array of symptoms may indicate the need for repair. Recognizing these signs is crucial in addressing issues before they escalate and cause significant disruptions. Whether it’s unusual noise, decreased performance, or visible damage, being attuned to these red flags can prompt timely action, ensuring that electric motor and pump systems remain operational and efficient.

Additionally, fluctuations in power consumption, overheating, and irregular vibrations are indicators that warrant attention from experienced repair professionals. By promptly addressing these symptoms, individuals and businesses can mitigate the risk of prolonged downtime and costly repairs, ultimately preserving the integrity of their electric motor and pump systems.

Signs that your electric motor or pump needs repair

The reliable operation of electric motors and pumps is contingent on various components working in harmony. However, several factors can contribute to malfunctions that impede the performance of these essential systems. Understanding the common causes of electric motor and pump malfunction is instrumental in preemptively addressing issues and maintaining operational efficiency.

One prevalent cause of electric motor and pump malfunction is the accumulation of debris and contaminants within the system. Over time, foreign particles can infiltrate the internal components, leading to friction, wear, and decreased performance. Furthermore, improper lubrication and inadequate maintenance practices can exacerbate the impact of debris, hastening the deterioration of critical components.

Electrical issues, such as overloading, voltage spikes, and insulation failures, also pose significant threats to the functionality of electric motors and pumps. These issues can result in overheating, motor burnout, and electrical failures, necessitating timely intervention by experienced repair professionals. Additionally, mechanical wear, bearing failures, and misalignment can compromise the structural integrity of electric motor and pump systems, leading to operational inefficiencies and potential damage.

Common causes of electric motor and pump malfunction

The importance of seeking professional electric motor and pump repair services cannot be overstated. Entrusting the repair and maintenance of these critical systems to skilled technicians offers a multitude of benefits, ensuring operational reliability, longevity, and cost-effectiveness in the long run.

Professional repair services encompass a comprehensive approach to diagnosing and addressing issues related to electric motors and pumps. From identifying faulty components to implementing precise repair techniques, skilled technicians are equipped to restore these systems to optimal functionality. By delving into the nuances of electric motor and pump repair, individuals and businesses can make informed decisions when seeking professional assistance.

Importance of professional electric motor and pump repair

Selecting the right electric motor and pump repair service provider is a pivotal step in ensuring the seamless functionality and longevity of these essential systems. With an array of options available, it’s imperative to consider several key factors that distinguish reputable service providers from the competition.

First and foremost, expertise and experience are paramount when selecting a repair service provider. An established track record of successfully diagnosing and repairing electric motors and pumps across various applications is indicative of a service provider’s proficiency and reliability. Additionally, certifications, licenses, and adherence to industry standards underscore a service provider’s commitment to quality and professionalism.

Furthermore, the availability of comprehensive maintenance programs and emergency repair services is an essential consideration. A service provider that offers preventive maintenance plans tailored to specific needs can help mitigate potential issues and prolong the operational lifespan of electric motors and pumps. Additionally, responsiveness and accessibility are critical, especially when urgent repairs are required to minimize downtime and operational disruptions.

Choosing the right electric motor and pump repair service provider

Before engaging the services of an electric motor and pump repair provider, it’s essential to consider several key factors to ensure a seamless and satisfactory experience. By evaluating these factors, individuals and businesses can make informed decisions and align their repair needs with a service provider capable of delivering reliable and efficient solutions.

First and foremost, assessing the service provider’s track record and reputation within the industry is paramount. Client testimonials, reviews, and references provide valuable insights into the service provider’s reliability, workmanship, and customer satisfaction. Additionally, verifying the service provider’s credentials, certifications, and adherence to industry standards instills confidence in their ability to deliver quality repair services.

Furthermore, transparency in pricing, service agreements, and warranty offerings is instrumental in fostering trust and clarity in the repair process. A reputable service provider will provide detailed explanations of the services offered, associated costs, and warranty coverage, ensuring that clients are fully informed and confident in their decision to engage the repair services.

Key factors to consider before hiring a repair service

The repair process for electric motors and pumps encompasses a systematic approach aimed at identifying, addressing, and rectifying issues to restore optimal functionality. Skilled technicians employ a series of diagnostic and repair techniques to ensure that electric motor and pump systems are restored to peak performance, mitigating downtime and operational disruptions.

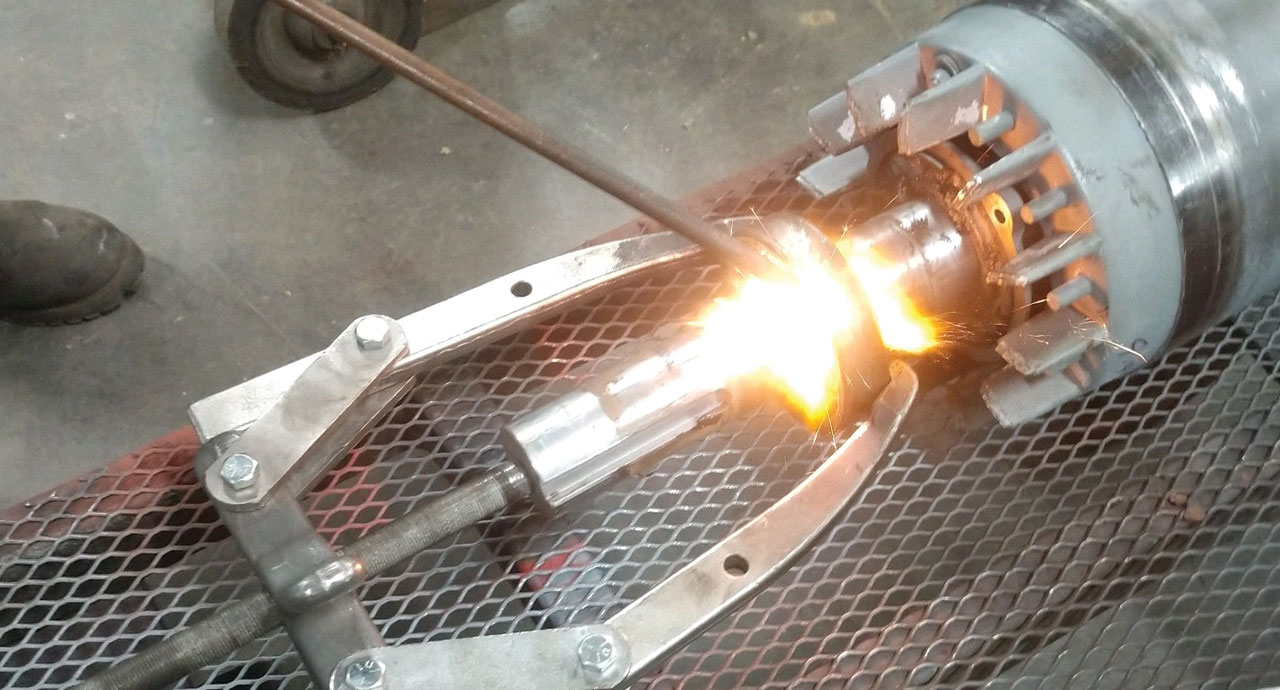

Upon initial assessment, technicians conduct comprehensive diagnostics to pinpoint the root causes of electric motor and pump malfunctions. This may involve testing electrical components, inspecting mechanical integrity, and assessing performance parameters to form a comprehensive understanding of the issues at hand. Through meticulous analysis, technicians can formulate tailored repair strategies to address the specific needs of each system.

Following diagnostics, repair procedures are executed with precision and expertise, encompassing a range of tasks such as component replacement, reconditioning, alignment adjustments, and system recalibration. Skilled technicians leverage specialized tools, industry-leading practices, and in-depth knowledge to execute repairs that adhere to stringent quality standards, ensuring the longevity and efficiency of electric motor and pump systems.

The repair process for electric motors and pumps

In addition to seeking professional repair services, implementing preventive maintenance measures is essential in preserving the functionality and longevity of electric motors and pumps. By adhering to proactive maintenance practices, individuals and businesses can mitigate the risk of unexpected malfunctions and optimize the performance of these critical systems.

Regular inspection and cleaning of electric motor and pump components are fundamental preventive measures that can prevent the accumulation of debris, contaminants, and wear-inducing particles. By maintaining cleanliness and addressing potential sources of contamination, the risk of premature wear and performance degradation can be significantly reduced.

Furthermore, adherence to scheduled lubrication routines, alignment checks, and electrical system assessments can prolong the operational lifespan of electric motors and pumps. Timely identification and resolution of minor issues through routine maintenance can prevent the escalation of problems, ultimately minimizing the need for extensive repairs and associated downtime.

Preventive maintenance tips for electric motors and pumps

When considering electric motor and pump repair services, understanding the associated costs is essential in making informed decisions and aligning repair needs with budgetary considerations. The cost of repair services is influenced by various factors, including the nature and extent of repairs required, the complexity of the systems, and the expertise of the service provider.

Initial diagnostics and assessments may incur nominal fees, providing insights into the scope of repairs and associated costs. While the cost of repairs varies based on the specific needs of each system, reputable service providers offer transparent pricing structures, detailed service estimates, and clear explanations of the factors contributing to the overall cost.

It’s important to note that investing in professional repair services is a proactive approach to preserving the operational integrity and efficiency of electric motors and pumps. By prioritizing the timely resolution of issues and the implementation of preventive maintenance measures, businesses and individuals can mitigate the risk of escalated repair costs and operational disruptions, ultimately safeguarding their investments in these essential systems.

Cost of electric motor and pump repair services

In conclusion, the seamless functionality of electric motors and pumps is instrumental in a myriad of applications, ranging from industrial operations to residential water distribution. Recognizing the signs of impending issues, understanding the common causes of malfunction, and prioritizing professional repair services are essential steps in ensuring the longevity and efficiency of these critical systems.

By selecting reputable service providers, embracing preventive maintenance measures, and addressing issues proactively, individuals and businesses can safeguard the operational reliability of their electric motors and pumps. The investment in professional repair services and proactive maintenance is a testament to the commitment to operational excellence, minimizing disruptions, and optimizing the performance of these indispensable components.

So, whether it’s a residential, commercial, or industrial setup, unlocking top-notch electric motor and pump repair services in your area is the key to seamless operations and sustained efficiency. Don’t let malfunctions derail your productivity – connect with reliable repair professionals and experience the assurance of optimal system performance.

In essence, the pursuit of unrivaled electric motor and pump repair services is a testament to the commitment to operational excellence, reliability, and efficiency. With the right knowledge, resources, and service providers at your disposal, you can navigate the realm of electric motor and pump repair with confidence, ensuring uninterrupted functionality and operational peace of mind.