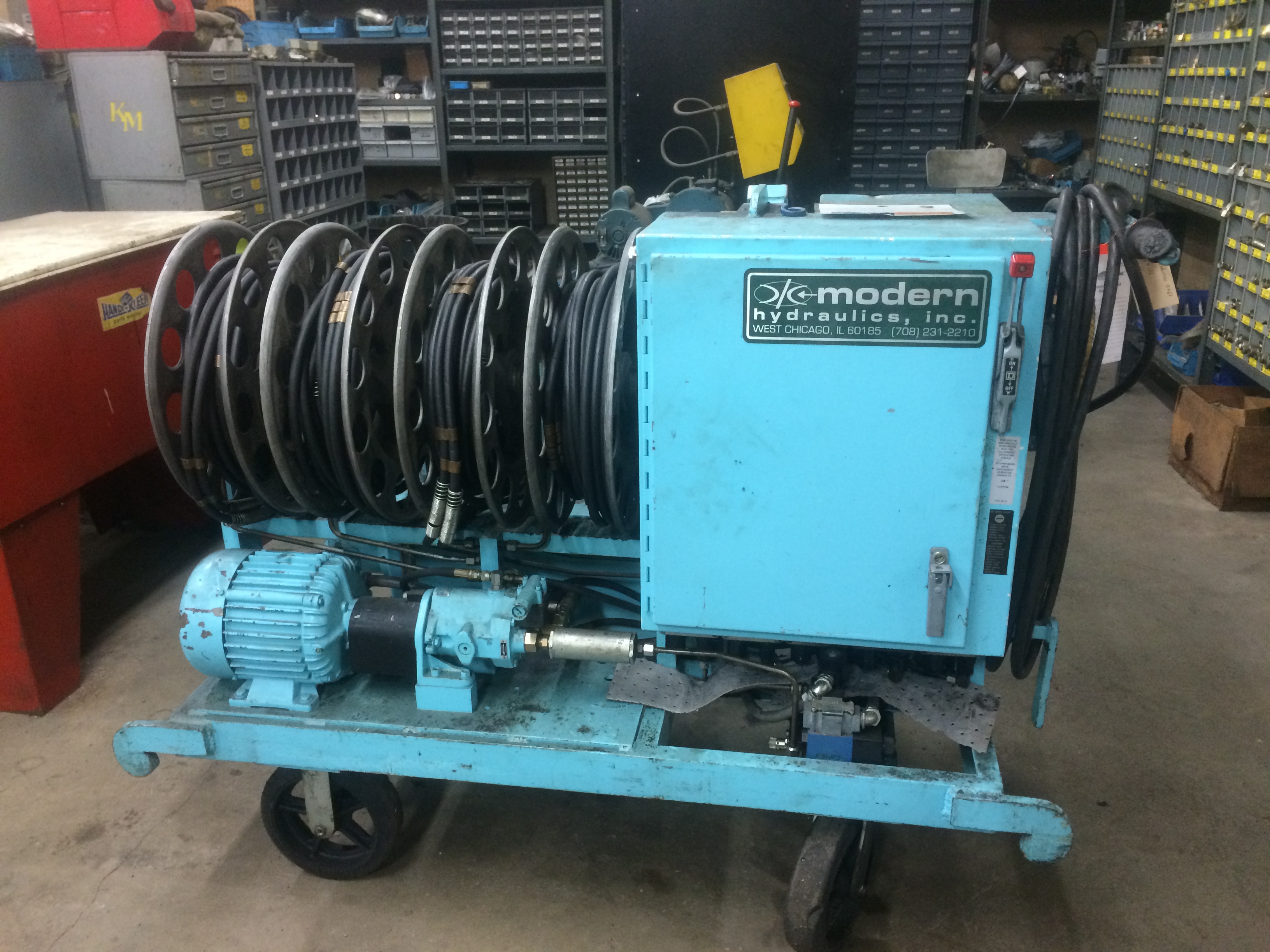

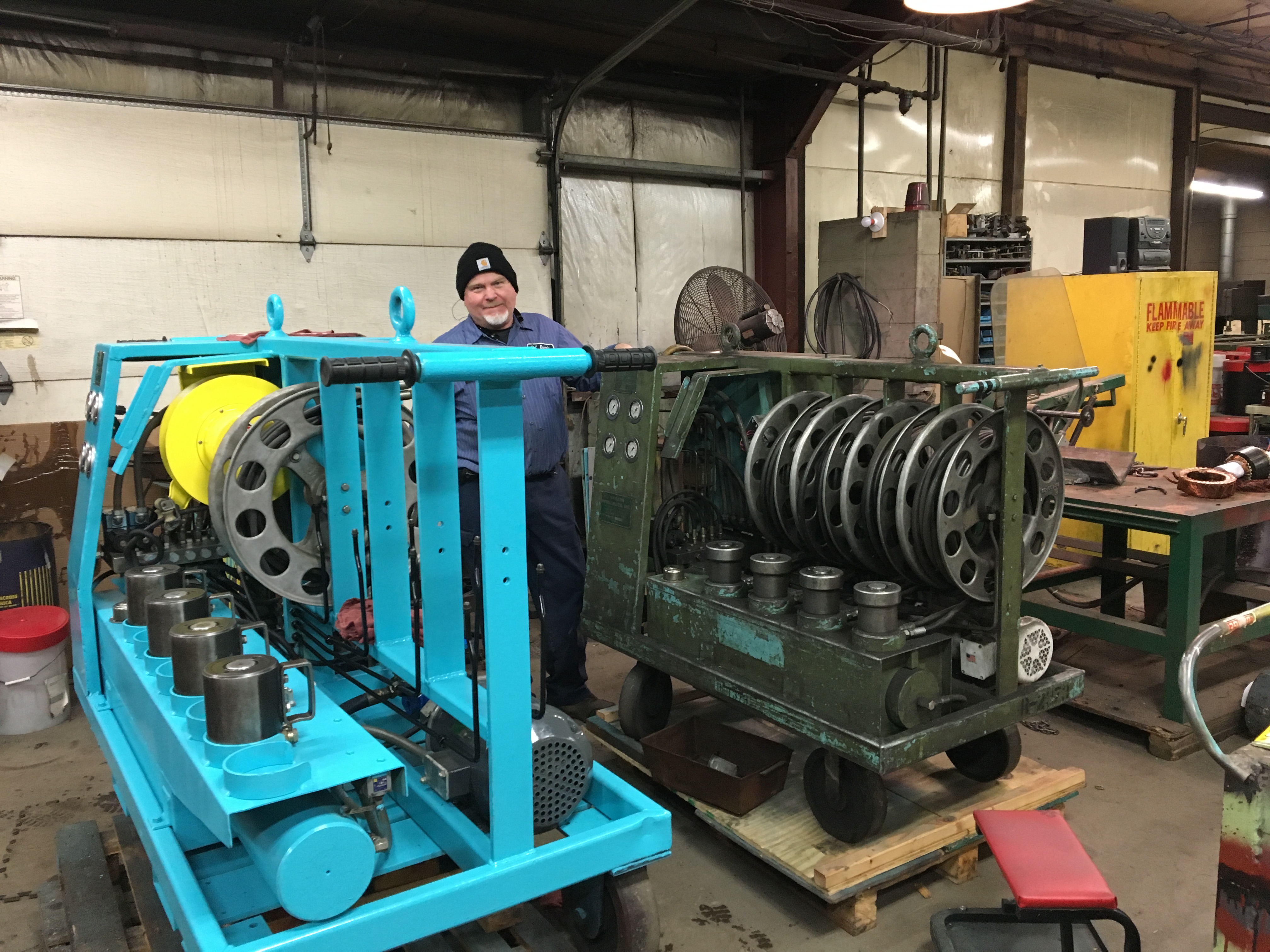

A 1980’s vintage Modern Hydraulics Die Separator, four “puck” manual model, received from Tesla Motors for repair and reconditioning. The Die Separators will be completely load tested to determine what system errors exist. All errors are corrected, all seals replaced, pump and motor rebuilt, new high pressure hoses, and new gages. The system is 24 hour load tested, the system unified , all gage readings confirmed. One year limited warranty.

The Modern Hydraulics Die Separators have long been preferred by industry due to their accuracy, reliability, and ease of use.

American Electric Motors: Refurbishing a 1980’s Vintage Modern Hydraulics Die Separator

Introduction

At American Electric Motors, we take pride in our expertise in refurbishing and restoring vintage machinery. In this article, we will delve into the process of refurbishing a 1980’s vintage Modern Hydraulics Die Separator, a remarkable piece of equipment used in various industries. Our meticulous approach, combined with our vast experience in restoring vintage machines, sets us apart from the competition. Join us as we explore the intricacies of refurbishing this iconic piece of industrial machinery.

Understanding the Modern Hydraulics Die Separator

The Modern Hydraulics Die Separator, introduced in the 1980s, revolutionized the manufacturing sector with its advanced hydraulic technology. This versatile machine is primarily used for separating, lifting, and transporting heavy dies in the metalworking industry. Its robust construction and precision engineering make it an indispensable tool for ensuring efficiency and productivity in die handling processes.

Assessing the Condition

When refurbishing a vintage Modern Hydraulics Die Separator, we begin with a thorough assessment of its current condition. Our team of skilled technicians meticulously inspects each component, identifying areas that require attention and replacement. By conducting a comprehensive evaluation, we gain insights into the machine’s history, identify potential issues, and determine the best course of action for restoration.

Disassembly and Cleaning

To restore the die separator to its former glory, we initiate the disassembly process. Carefully dismantling the machine allows us to access every part and scrutinize its condition. We clean each component meticulously, removing dirt, debris, and any signs of corrosion. This meticulous cleaning process ensures optimal performance and longevity of the machine once restored.

Replacement of Components

During the evaluation phase, we identify components that have reached the end of their lifespan or no longer meet the required standards. Our team sources high-quality replacement parts, ensuring they align with the original specifications of the machine. By using authentic components, we guarantee the functionality and durability of the refurbished Modern Hydraulics Die Separator.

Reassembly and Calibration

Once all necessary components have been replaced, we proceed with the reassembly of the die separator. Our skilled technicians meticulously follow the original assembly instructions, ensuring every part fits precisely and functions seamlessly. After the reassembly, we conduct thorough calibration and testing to guarantee optimal performance and precision.

Performance Testing and Quality Assurance

To ensure the complete restoration of the Modern Hydraulics Die Separator, we subject it to rigorous performance testing and quality assurance measures. Our team conducts comprehensive assessments, examining factors such as lifting capacity, accuracy, hydraulic system functionality, and overall operational efficiency. Only after passing these tests with flying colors, do we consider the refurbishment process complete.

Benefits of Refurbishing a Vintage Modern Hydraulics Die Separator

- Cost Savings: Refurbishing a vintage machine is a cost-effective alternative to purchasing a new one. By leveraging our expertise, you can breathe new life into your old machinery while saving a substantial amount of money.

- Environmental Sustainability: Opting for refurbishment contributes to sustainable practices by extending the life cycle of existing machinery. It reduces waste, conserves resources, and minimizes the carbon footprint associated with manufacturing new equipment.

- Preservation of Industrial Heritage: Vintage machines like the Modern Hydraulics Die Separator hold historical significance. Through refurbishment, we preserve these pieces of industrial heritage, keeping the spirit of innovation alive for future generations.

- Enhanced Performance: Our meticulous restoration process ensures that the refurbished die separator performs at its peak